If the rolled metal moves out of place or the machine malfunctions you might end up with a split piece of metal through its width leading a dent or thinned out area.

Defects and remedies in sheet metal.

Of defects are discussed 232 during massive and during sheet metal processing.

To be fairly.

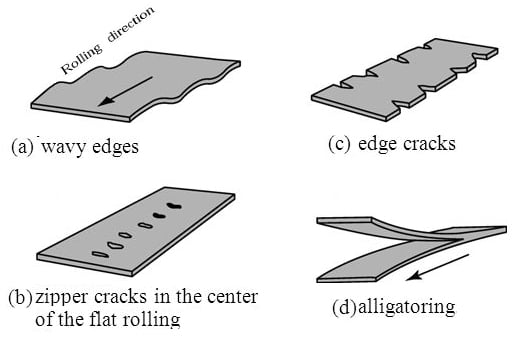

Another common defect in sheet metal rolling involves the splitting of a workpiece.

Incomplete penetration occurs when the depth of the welded joint is insufficient.

Until recently defects have tended to draw little attention from academic researches into the mechanics material below processing a wide because are mostly devoted range to considering which occur ideal materials and processes which work successfully.

These are the few welding defects causes and remedies.

These are critical manufacturing defects in the forming of ahss and uhss.

This effect is called crown.

Usually these defects happened during previous work with the metal.

How to prevent metal rolling defects.

Prior to working with a metal rolling machine a piece of metal might have impurities such as.

This can cause an uneven roll with various amounts of pressure throughout the piece.

Incorrect blank shape and or size.

There are two reasons behind this defect.

One is the improper handling another one is the elasticity of sheet metal forming materials.

One of the primary defects that occurs in deep drawing operations is the wrinkling of sheet metal material generally in the wall or flange of the part.

Crown and wedge when sheet metal is rolled down to your ordered thickness the center width position of the master coil is slightly thicker and the coil edges are slightly thinner than the body of the coil.

Clamping down on the alligatoring defect in sheet metal rolling when you are using a rolling mill you want smooth and perfectly shaped metal for one of many different applications.

Sheet metal rolling defects have two different categories.

Wrinkles splits and springback are the three most common defects encountered during sheet metal stamping.

The reason behind it is that welding positions are misaligned.

Penetration is defined as the distance from the base plate top surface to the maximum extent of the weld nugget.

Springback or final part deviation from nominal incorrect process or number of forming tools.

The flange of the blank undergoes radial drawing stress and tangential compressive stress during the stamping process which sometimes results in wrinkles.

Excessive thinning thickening of the sheet during forming.

Internal structural rolling defects.

Below i mentioned the welding defects with remedies.

During the rolling process a piece of metal will experience a different amount of reduction in certain areas.

The main reasons for the cracking are over stretching or stress concentration.